The connective task has two main areas of work, TSV and flip-chip bonding development.

Indium_BumpYield_28032014.pptx: Bump Yield Studies March 2013

Flip-chip bonding at STFC-RAL

STFC/RAL are developing a fine pitched Indium flip-chip process. The samples first have an under bump metal (UBM) layer deposited upon them where the bump is to be grown. The UBM used to date is Ti/W, Ni, Au. The Ti/W is an adhesion layer to the Aluminium pad of the device. The nickel is the solderable metal layer and the Au is an oxidation barrier. The indium is deposited in a thermal reactor at RAL. The Indium is heated under vacuum and condenses on the sample that is held at a lower temperature. The samples can then be flip-chipped bonded. The flip-chip process is to work at room temperature or slightly elevated temperatures. There is some worry that the Indium bumps require more pressure to form a bump than should be the case. One suggestion for this high pressure is that the gold used in the UBM is moving into the Indium and forming an Indium/Gold alloy which requires more force to deform. A SEM/FIB/EDX study of an Indium bump formed on a silicon substrate was performed in Glasgow to try and test the hypothesis that the gold had moved into the Indium. The report is found here:- Report_on_SEM_Secondary_electron_images_and_EDX_measurements_on_In_bumps_from_RAL.docx: Report on SEM for Indium bump from RAL

First Indium Flip-chip bonded FE-I4

The first indium assembly wafer ID : VMB6NJH die 3 Sensor : CPII Live FE-I4 MPI Guard IBLIndium_BumpYield_28032014.pptx: Bump Yield Studies March 2013

Indium Flip-Chipped Modules September 2014

Indium bumps require pressure only to make connections so no high temperatures are required to melt alloy, which reduces bowing effects.

Modules under test:

| ID | Bond Force | Comment |

|---|---|---|

| 14-07-24-S2 | 20kg | biased to 40V |

| 14-07-25-S2 | 10kg | short on VDDA line |

| 14-07-25-S4 | 5kg | biased to 40V (operated at 20V) |

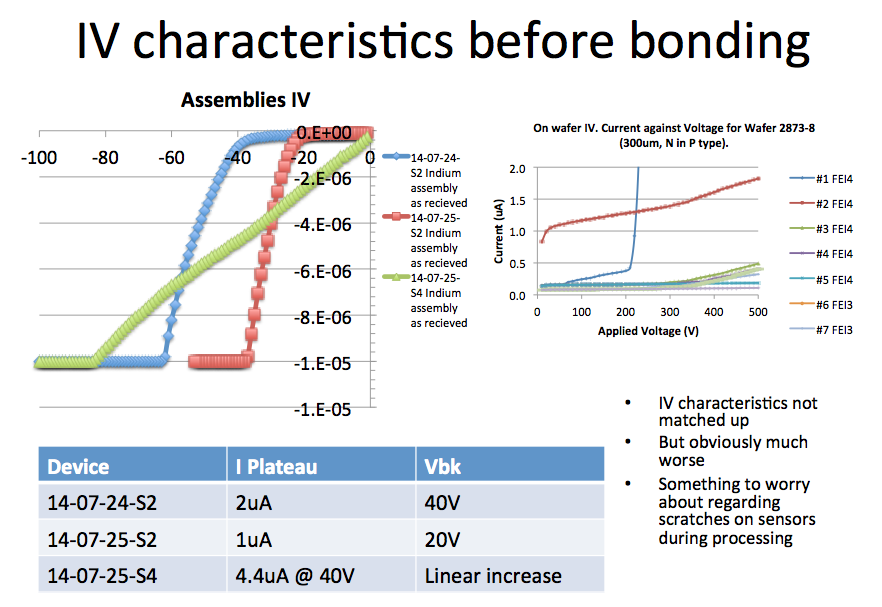

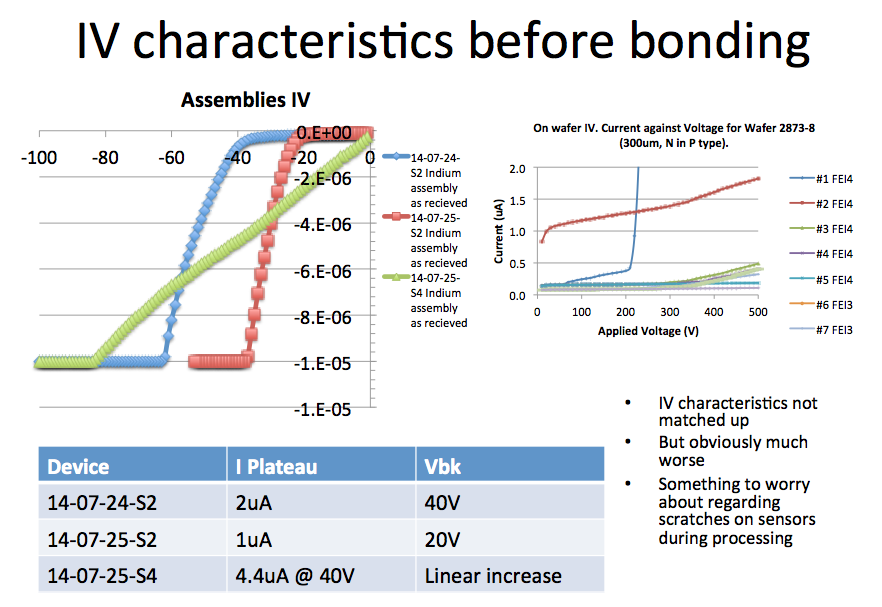

IV Scans

IV Scans on wafer and after processing

Characterisation

USBPix

Bump yield studies performed in August 2014 by Dan Smaranda and Richard Bates 21082014_Indium-DanSmaranda.pdfRCE System

All modules tuned to and operated at 3000e threshold, 10ToT @ 16ke reference charge.Tuning

Module 14-07-24_S2: Tune to 3000e, 10ToT @ 16ke 14-07-24_S2_3000eTuning.pptx Module 14-07-25_S4: Tune to 3000e, 10ToT @ 16ke 14-07-25_S4_3000eTuning.pptxBump Yield Studies

Bump Yield assessed by performing Threshold Scans with and without sensor bias and performing source scans with Strontium-90 beta source and Americium-241 60keV gamma ray source. Indium-Characterisation_0914.pptxBump yield results

| Module | Bond Force | Bump Yield (Sigma plot) |

Bump Yield (Source Scans) |

|---|---|---|---|

| Indium1 | ? | 99.48% | 99.38% |

| 14-07-24-S2 | 20kg | 82.85% | 82.35% |

| 14-07-25-S4 | 5kg | 23.37% | 22.54% |

Comments

TSV

Details of the TSV activity are given on the next page. -- RichardBates - 2011-06-09| I | Attachment | History | Action | Size | Date | Who | Comment |

|---|---|---|---|---|---|---|---|

| |

14-07-24_S2_3000eTuning.pptx | r1 | manage | 159.3 K | 2014-10-01 - 14:43 | KateDoonan | |

| |

14-07-25_S4_3000eTuning.pptx | r1 | manage | 154.1 K | 2014-10-01 - 14:43 | KateDoonan | |

| |

21082014_Indium-DanSmaranda.pdf | r1 | manage | 598.7 K | 2014-09-25 - 13:38 | KateDoonan | Bump Yield Studies by Richard Bates and Dan Smaranda 08/2014 |

| |

Indium-Characterisation_0914.pptx | r1 | manage | 580.0 K | 2014-09-25 - 13:39 | KateDoonan | Bump yield studies by Kate Sexton |

| |

Indium_BumpYield_28032014.pptx | r1 | manage | 636.5 K | 2014-04-03 - 07:27 | RichardBates | Bump Yield Studies March 2013 |

| |

Report_on_SEM_Secondary_electron_images_and_EDX_measurements_on_In_bumps_from_RAL.docx | r2 r1 | manage | 9890.4 K | 2012-06-14 - 14:27 | RichardBates | Report on SEM for Indium bump from RAL |

| |

Screen_Shot_2014-09-25_at_14.50.52.png | r1 | manage | 156.1 K | 2014-09-25 - 13:51 | KateDoonan | IV Characteristics of Modules before and after processing |

Topic revision: r8 - 2014-10-20 - RichardBates

Ideas, requests, problems regarding TWiki? Send feedback